Does the meltblown fabric inspection report measure the filtration efficiency of BFE and PFE?

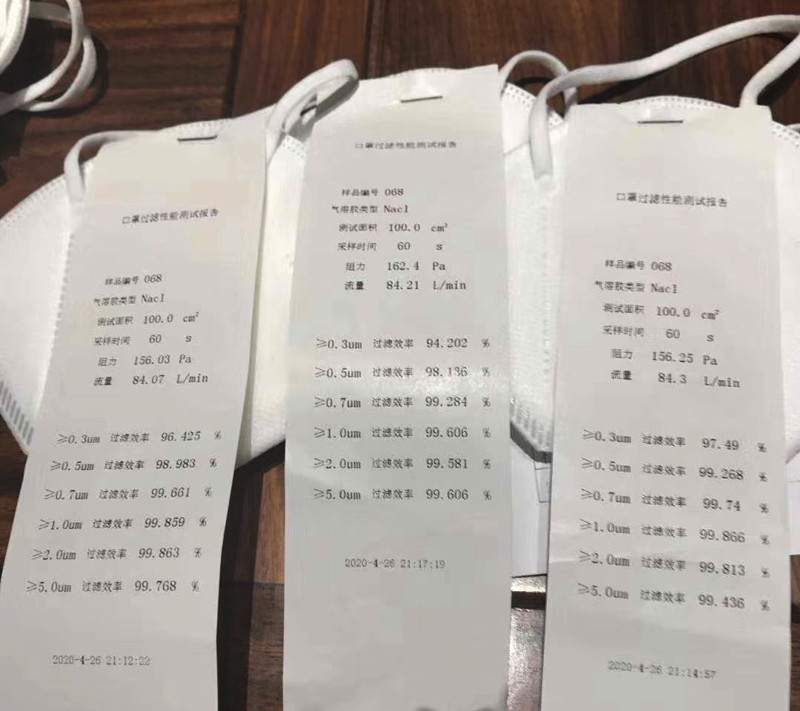

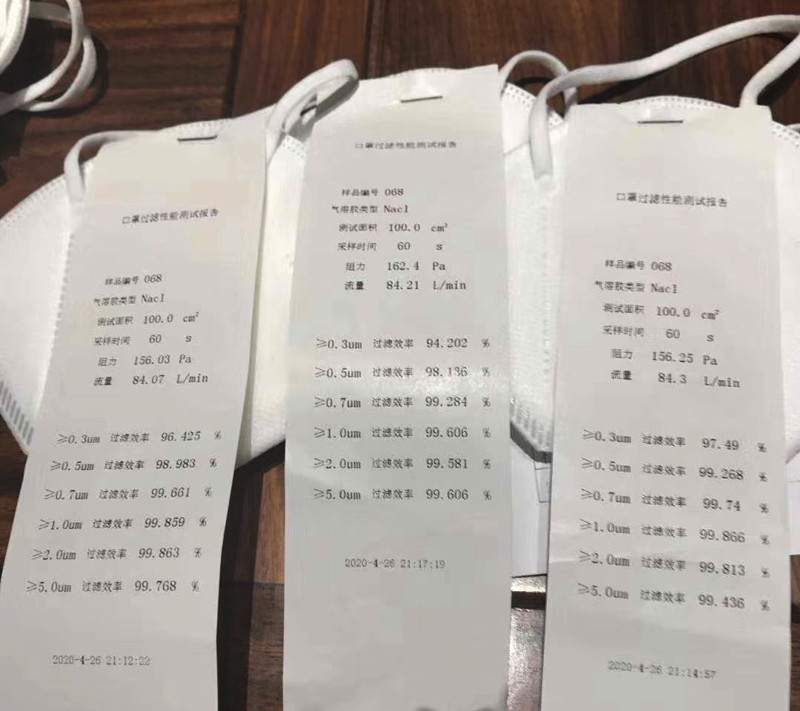

Melt-blown cloth is the core of the facial masks. At present, the detection of the melt-blown cloth mainly depends on its resistance index, filtration efficiency index, microbial index, etc. The reference for the detection is the GB2626-2003 standard.

Medical surgical masks generally have three layers, the inner and outer layers are non-woven fabrics, and the middle filter layer is melt-blown fabric.

"Melt-blown cloth" is commonly known as the "heart" of facial masks. It has good filtering, shielding, heat insulation and oil absorption properties. It is an important raw material for the production of medical surgical face masks and N95 face masks. Medical face masks are mainly composed of three layers of non-woven fabrics. The inner layer is ordinary non-woven fabric; the outer layer is water-repellent non-woven fabric, which is mainly used to isolate the liquid sprayed by the patient; the middle filter layer is a polypropylene melt-blown non-woven fabric that has been treated with electret; After the production is completed, it should be sterilized by epoxy Z alkane and allowed to stand for 7 days for volatile toxicity. After being sealed and packaged, it is shipped in a box.

The main raw material of melt-blown cloth is polypropylene, which is an ultra-fine electrostatic fiber cloth with a fiber diameter of about 2 microns. Its diameter is only one tenth of the fiber diameter of the outer layer of the face mask, which can effectively capture dust. When the droplets containing the virus are close to the meltblown cloth, they will also be electrostatically adsorbed on the surface and cannot penetrate. Therefore, it is a necessary raw material for the production of filter masks.

The melt-blown material is made of hot-melted self-fibers, and the thicker thickness of the non-woven fabric is produced by the melt-blown method. The fibers are randomly arranged with the interlayers, forming a multi-bend channel structure of the melt-blown material. ) Will collide with the fiber and be stranded.

The filtering mechanism of medical face masks is Brownian diffusion, entrapment, inertial collision, gravity settling and electrostatic adsorption. The first four are physical factors, that is, the characteristics of the non-woven fabric produced by the melt-blown method, the filterability is about 35%; this is not up to the requirements of medical masks, and we need to perform electret treatment on the material to make the fiber Charge it and use static electricity to capture the aerosol where the new coronavirus is located.

The electret treatment of electrostatic adsorption is to achieve the capture of new coronavirus droplets (aerosols) by the Coulomb force of charged fibers. The principle is to make the surface of the filter material wider, and the ability to capture particles can be grabbed, while the charge density increases, and the adsorption and polarization effects of the particles are stronger. Extreme treatment can achieve 95% filterability without changing respiratory resistance, and can effectively prevent viruses. Masks should ensure comfortable ventilation while achieving the barrier effect. The inhalation resistance of medical masks generally does not exceed 343.2 Pascals (Pa), and the inhalation resistance of civilian masks is less than 135 Pascals (Pa).

P.S we offer five layers KN95 face masks, two layers are meltblown fabric.